Empowering frontline heroes with real-time insights, automation, and peace of mind

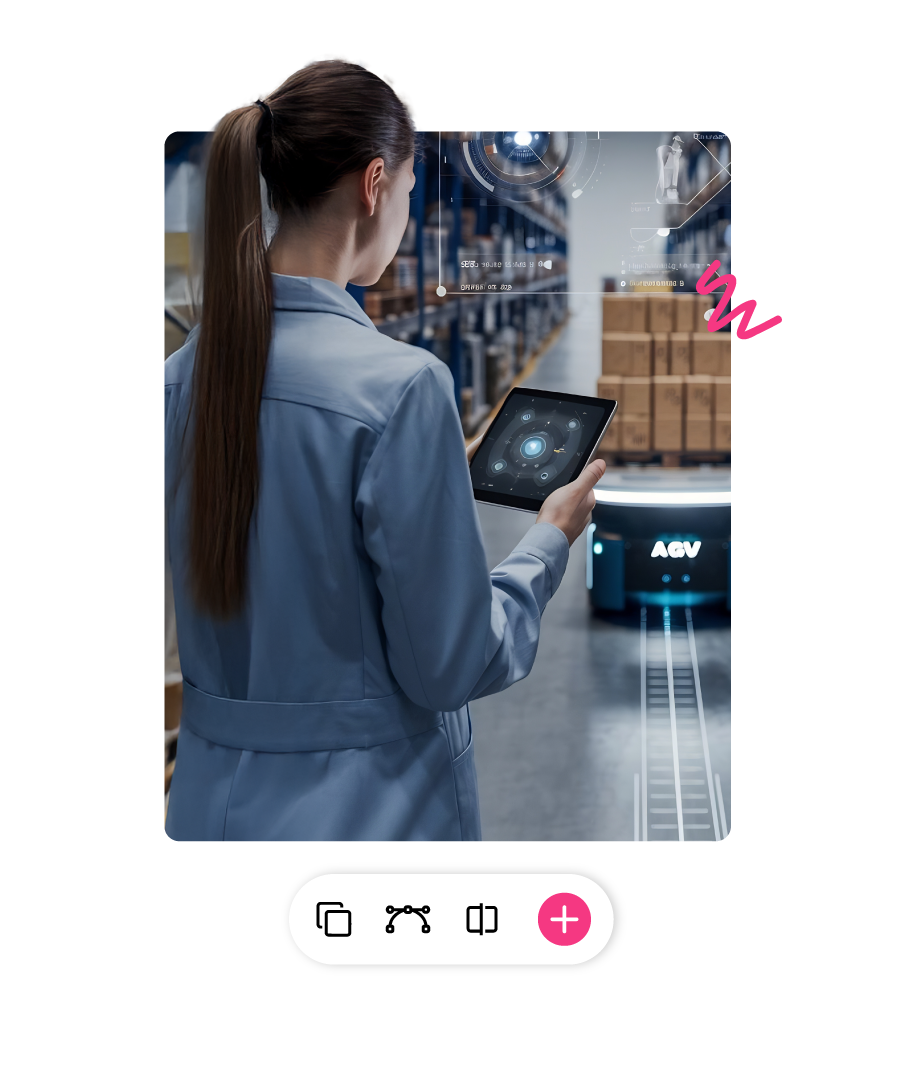

Access digital SOPs, scan job orders via QR codes, and use smart sensors to monitor equipment status

Use mobile dashboards to monitor WIP status, workforce allocation, and issue escalations across workstations

Receive AI-based alerts for predictive maintenance, access equipment history via mobile CMMS, and use AR to troubleshoot breakdowns

Usage : AI analyzes historical orders, seasonal trends, and machine capacity to auto-generate optimal production schedules.

Impact : Reduces planning time, increases throughput, and improves on-time delivery by up to 30%.

Usage : Each stage of the order process is digitally logged, showing where a job is — cutting, molding, painting, testing, etc.

Impact : Reduces time lost in manual updates, increases transparency, and simplifies audits.

Leverage AI to auto-schedule jobs based on capacity, due dates, raw material availability, and machine status

Use RFID and IoT-based systems for real-time inventory visibility, and QR-code based material tracking for in-line delivery

Use AI-powered vision systems and digital checklists for real-time inspection and traceability tagging

Use AR/VR modules for operator training, auto-log attendance and certifications, and manage skill matrix digitally

Usage : AI engines analyze machine availability, worker shifts, material readiness, and due dates to generate the most efficient job sequencing.

Impact : Reduces changeovers, increases throughput, and ensures on-time delivery of multiple concurrent orders.

Usage : Machines directly feed status, quantity, and error signals back to the system during the order lifecycle.

Impact : Minimizes manual data entry, detects anomalies in real time, and accelerates issue resolution.

Usage : Smart systems send real-time alerts to supervisors when orders fall behind SLA, face quality issues, or go off track.

Impact : Prevents escalation into bigger problems, ensures timely corrections, and boosts delivery success rates.

Usage : Smart dashboards show live order statuses — from initiation to completion — with updates from machines, operators, and material movement.

Impact : Enhances visibility, reduces follow-up chaos, and enables proactive decision-making for delays or bottlenecks.

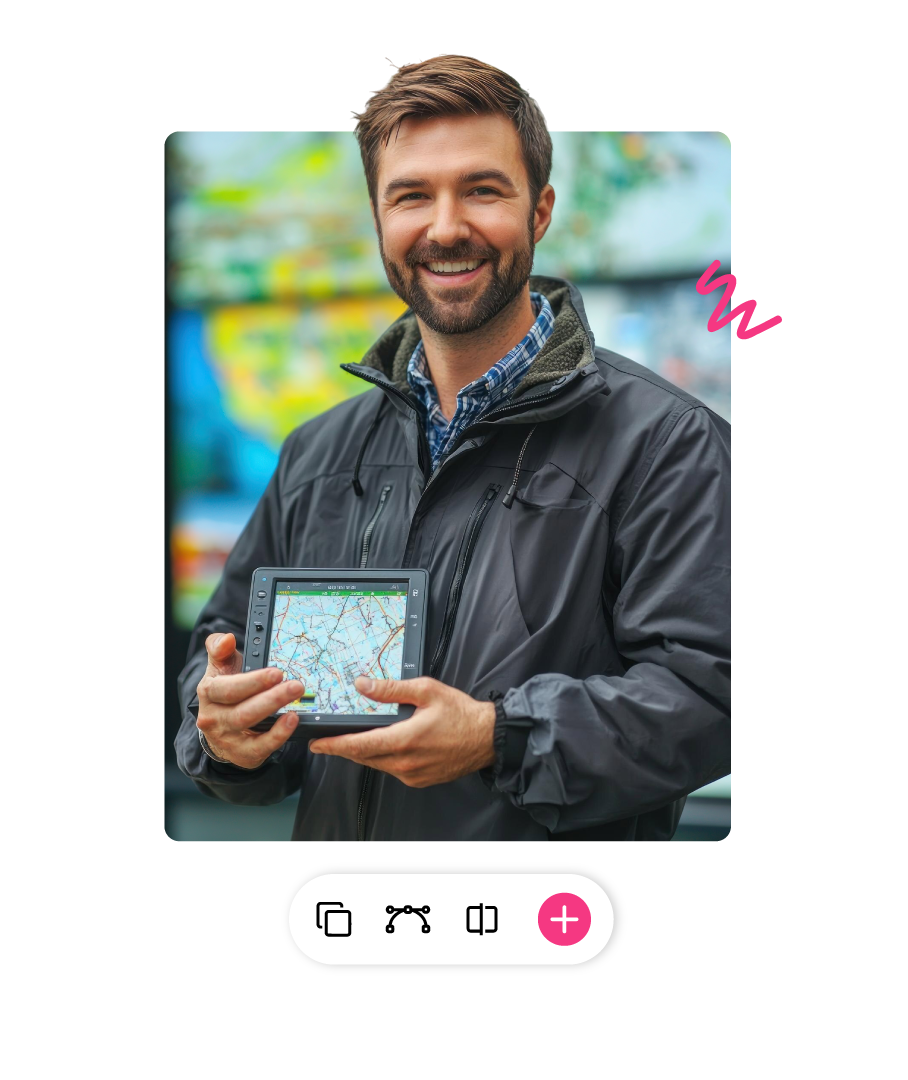

Usage : Supervisors track order progress, update shift assignments, mark delays, and close jobs from a mobile app synced with central systems.

Impact : Enhances agility on the floor, eliminates paperwork, and improves response time.

Usage : Based on line loads or machine status, smart systems reroute manufacturing orders to alternate lines or backup machines automatically.

Impact : Reduces idle time, improves line balancing, and avoids bottlenecks.

Access central dashboards, production analytics, OEE reports, and exception alerts from mobile or desktop

From operators to plant heads – unlock productivity, quality, and visibility with role-driven intelligence.