Modernize inspection workflows with drone intelligence, digital audits, and real-time visual validation to drive operational safety

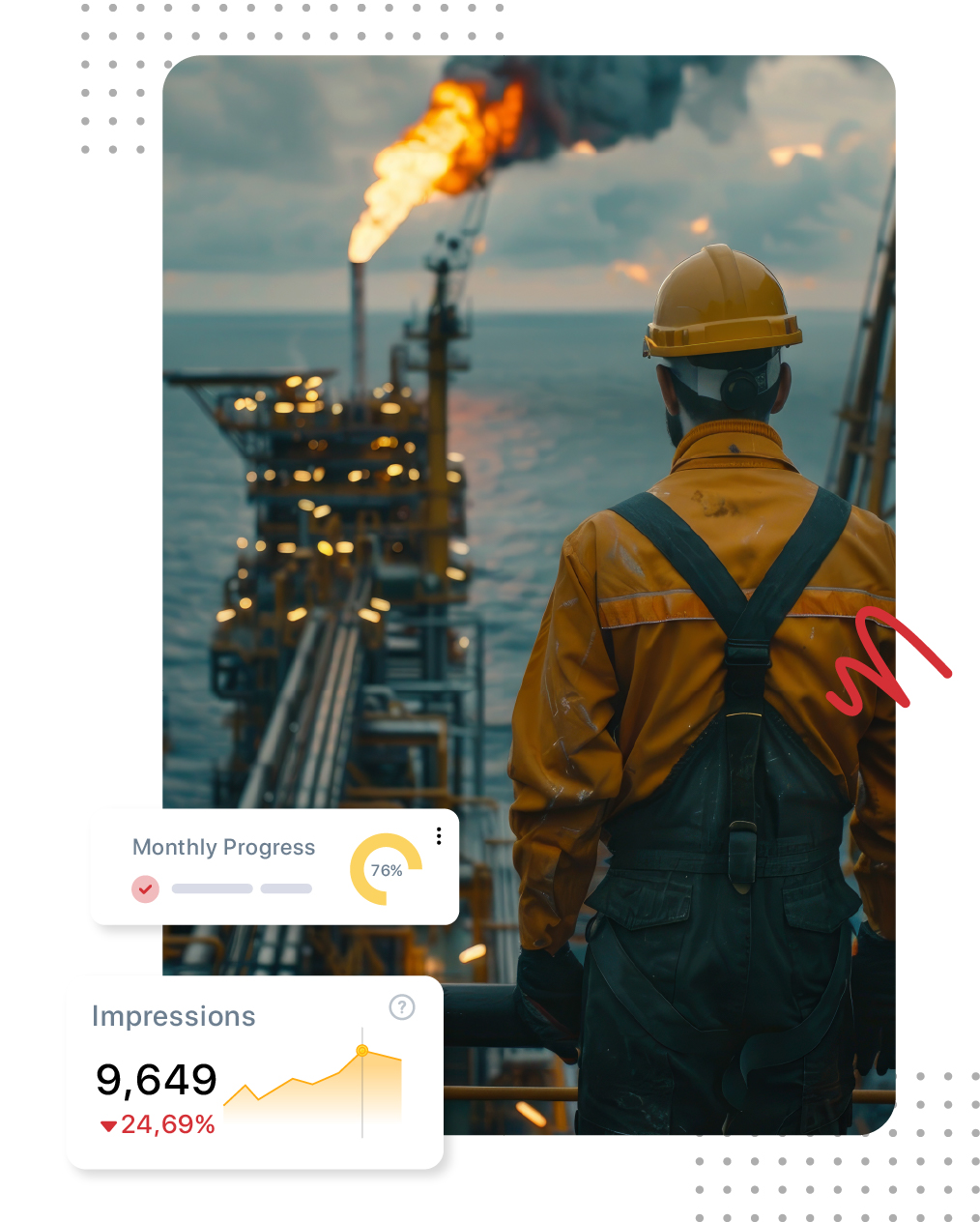

Track, report, and act on emissions, waste, and environmental impact in full alignment with global sustainability goals

Precision at Every Stage — From Core to Consumer

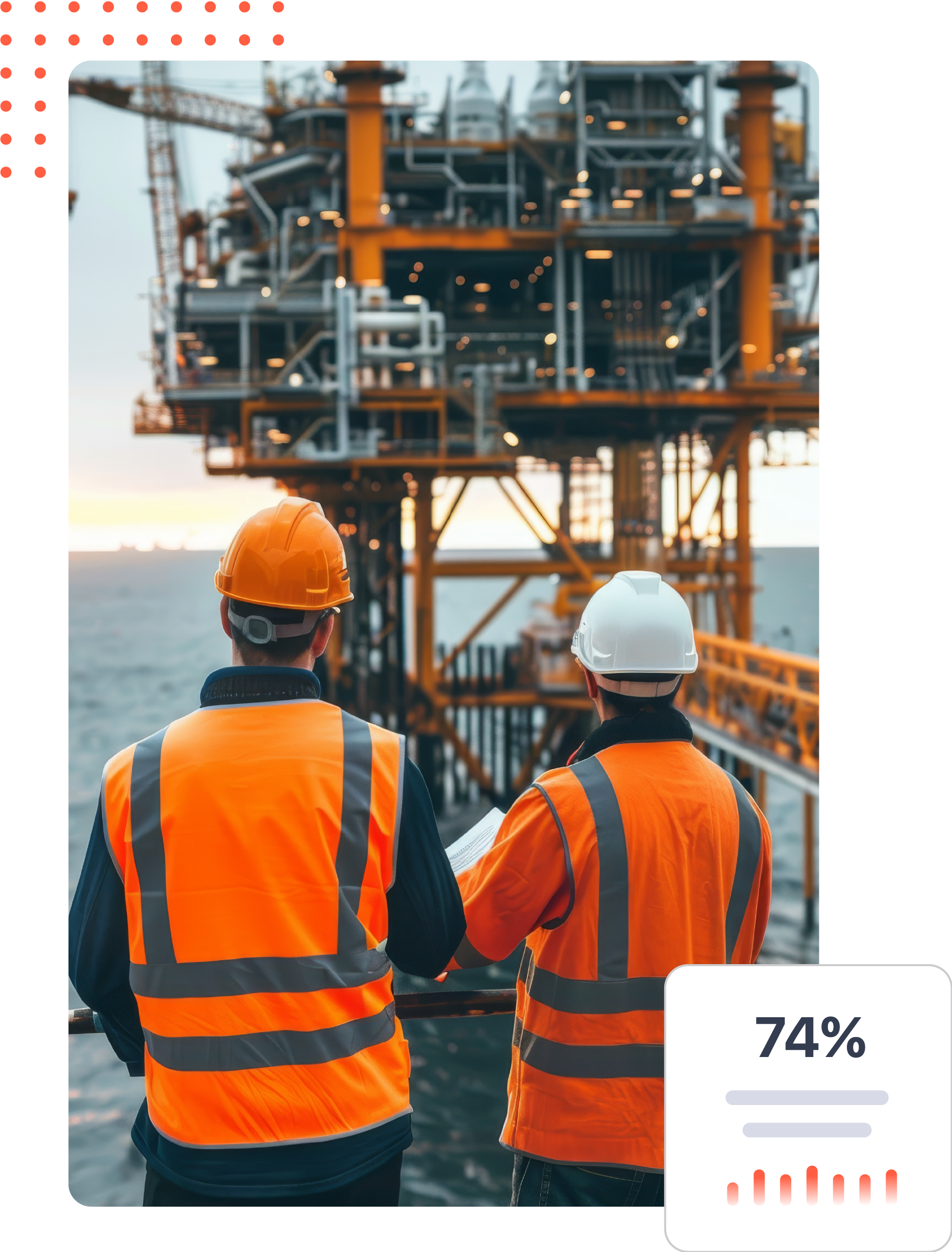

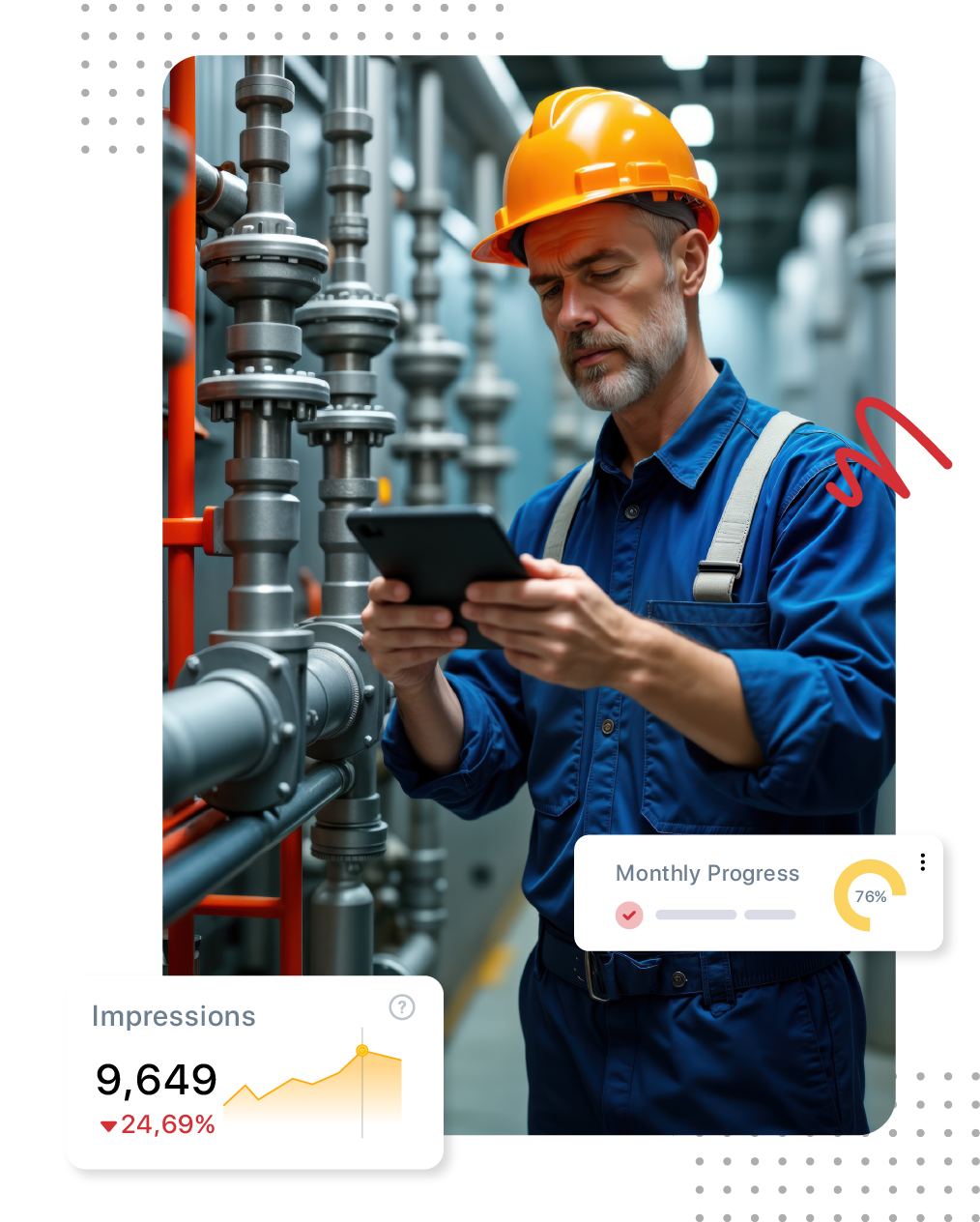

Inspect Smarter, Operate Safer

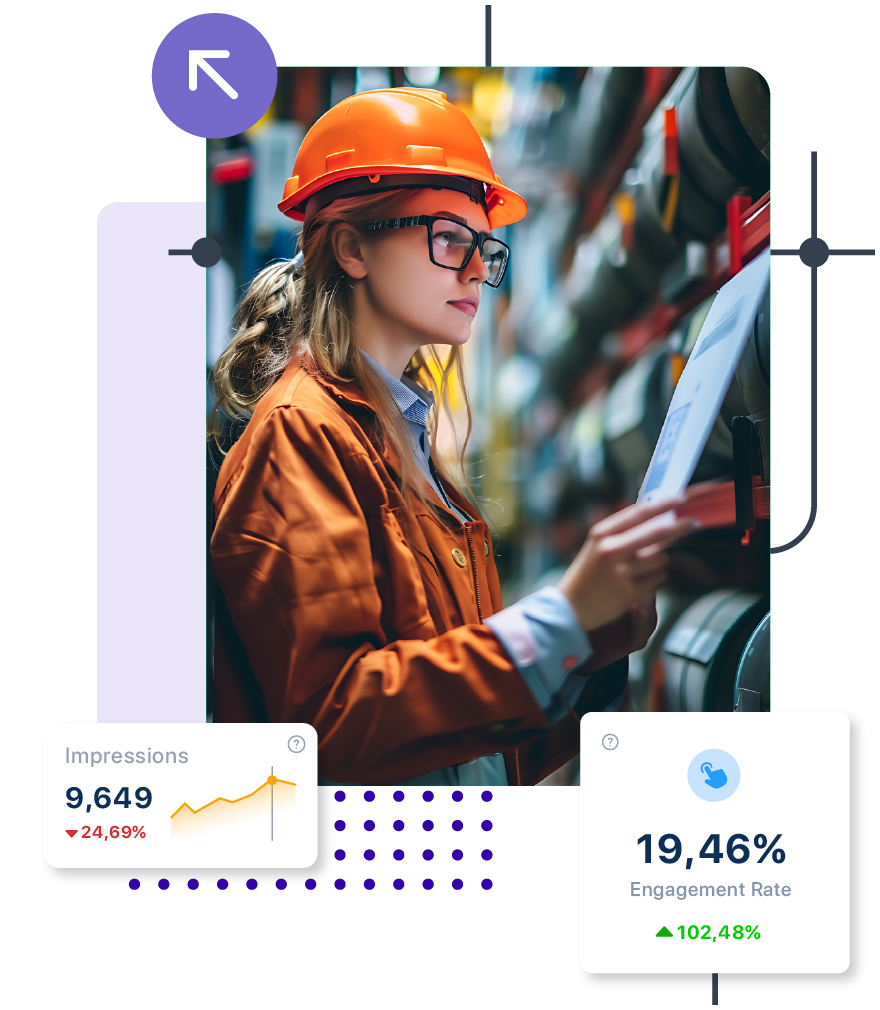

Lab Automation. Global Validation

Usage : Centralize chemical, material, environmental, fuel, lubricant, and corrosion testing across upstream, midstream, and downstream operations.

Impact : Reduces test turnaround time, ensures data traceability, and guarantees conformance to global standards (ISO, ASTM, API).

Usage : Conduct intelligent remote and on-site inspections of pipelines, refineries, offshore platforms, and equipment using drones, IoT, and AI.

Impact : Minimizes manual errors, reduces inspection costs, and ensures 100% audit readiness.

Verified at Origin. Trusted at Destination

Comply. Conserve. Continue

Quality Assured, Before It Ships

Know the Risk. Avoid the Fail

Usage : Manage end-to-end lab processes with integrated workflows, real-time sample tracking, and automated certificate generation.

Impact : Enhances lab productivity, ensures data integrity, and facilitates seamless client reporting.

Usage : Generate and manage quality and safety certifications (like ISO, API Q1, Q2, IECEx) in real-time with digital audit trails.

Impact : Reduces compliance delays, eliminates paperwork, and builds customer trust.

Usage : Digitally track quantity, quality, and condition of oil, gas, LNG, and petrochemical shipments across loading/unloading points.

Impact : Prevents cargo disputes, improves transparency, and speeds up payment cycles.

Usage : Enable remote monitoring and lab-based testing of air, water, and soil across oilfield operations, with ESG-compliant reporting tools.

Impact : Avoids fines, improves stakeholder transparency, and supports green goals.

Usage : Digitally inspect vendor-supplied equipment (valves, pipes, pumps, turbines) before dispatch through AI-enhanced quality checks.

Impact : Minimizes project risks, ensures material reliability, and accelerates deployment.

Usage : Monitor corrosion, thickness, vibration, and pressure in critical assets with risk scoring and automated alerts.

Impact : Reduces downtime, extends asset life, and supports proactive maintenance planning.

Usage : Offer skill assessments, e-learning, and certification programs for technicians, engineers, and QHSE professionals.

Impact : Builds a compliant, skilled workforce and improves operational safety.

Usage : Track carbon emissions, waste output, water usage, and sustainability performance in real time, with automated ESG scorecards.

Impact : Enables ESG disclosures, stakeholder transparency, and global green compliance.

Usage : Analyze used oil and lubricants for wear particles, viscosity, and contaminants using AI for early equipment failure detection.

Impact : Reduces machinery breakdown, extends maintenance intervals, and cuts costs.

Make every barrel greener — with smart tools to measure, reduce, and disclose Scope 1, 2, and 3 emissions effectively

Analyze wear, detect faults early, and extend the life of critical machinery with intelligent fluid diagnostics

Build trusted supply chains — assess, audit, and certify suppliers with dynamic compliance and performance metrics