From Chaos to Cohesion – Streamline, Collaborate, Succeed

Deploy mobile-enabled inspections during live operations to detect deviations in real-time. Bring teams together with collaborative workflows, real-time alerts, and corrective action loops

Run inspections based on time, quantity, shift, or custom triggers like equipment changes or customer complaints

Tag batches, products, or machines with QR codes for instant inspection access, history lookup, or defect tracking

Automatically record who did what, where, and when—building a strong trail of actions, evidence, and accountabilit

Usage : Conduct structured inspections for raw materials, in-process checks, final goods, packaging, and shipment—fully digitized and mobile-enabled.

Impact : Reduces defect risk, eliminates manual paperwork, and enforces quality compliance across all production stages.

Usage : Replace slow traditional inspection agencies with real-time inspection collaboration, QR-linked data capture, and remote visibility for all stakeholders.

Impact : Saves cost, improves inspection speed, and increases trust between suppliers, factories, and brands.

Immerse. Influence. Inspire – Learning That Drives Action. Embed rich media—videos, infographics, SOPs, and best practices—directly into inspection forms and guidance screens for easy access during audits or tasks.

Connected Intelligence – Efficiency Empowered by IoT.Integrate environmental, operational, and equipment sensors to enable smart inspections and auto-log real-time data into inspection workflows.

Where Accuracy Meets Action – Monitor, Map, Mobilize. Enable real-time location-based inspections using geofencing and GPS. Share inspection reports, images, and data instantly with stakeholders and supervisors

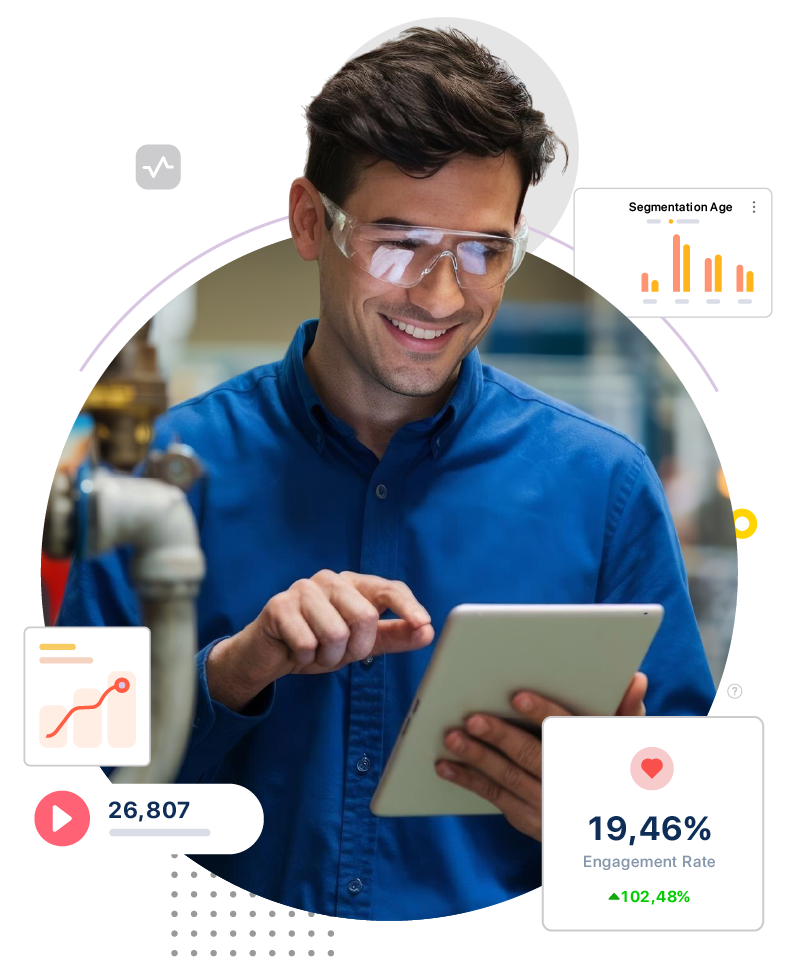

Quantify Quality. Amplify Performance – Measure. Improve. Excel. Track inspection metrics such as defect density, closure rate, inspection frequency, and compliance levels in rich dashboards and reports.

Usage : Capture and tag product conditions, defects, line performance, and packaging status with visual proof during each inspection.

Impact : Adds transparency, supports dispute resolution, and makes reports more credible and audit-ready.

Usage : Auto-generate branded PDF reports including timestamped records, inspector notes, media, and action plans—with embedded QR codes to validate authenticity.

Impact : Elevates documentation standards, improves compliance, and simplifies audit trails.

Usage : Track inspection activity, scores, and compliance across multiple factories, vendors, or regions with centralized dashboards.

Impact : Builds transparency into your entire supply chain, improves vendor governance, and strengthens sourcing decisions.

Usage : Create custom product testing templates for textile, food, electronics, packaging, or garments based on buyer specs or regulatory standards.

Impact : Ensures that field tests match lab conditions, helping reduce post-shipment failures and recalls.

Usage : Flag issues, assign responsible teams, and monitor corrective action closures with deadlines and digital proof.

Impact : Ensures follow-through on quality issues, improves accountability, and supports continuous improvement culture.

Usage : Score suppliers and factories based on inspection outcomes, defects per batch, issue recurrence, and timeliness.

Impact : Empowers better sourcing, performance benchmarking, and quality strategy planning.

Usage : Allow brand customers and QA heads to supervise inspections remotely with live video, real-time chats, and on-the-spot approvals.

Impact : Reduces travel cost, speeds up quality verification, and increases trust across borders.

Usage : Verify that every carton, label, barcode, and brand identity element is correct and consistent before shipment.

Impact : Reduces rejections at warehouses and customer returns due to mislabeling or packaging errors.

Usage : Brands can approve specific inspectors, co-create checklists with vendors, and create shared visibility across teams.

Impact : Improves standardization, builds long-term quality partnerships, and eliminates the “us vs. them” mentality.

Standardize inspections across geographies and teams. Support multiple languages, devices, and user roles for inclusive adoption

Let anyone on the factory floor report a defect, near-miss, or suggestion, with optional media and location