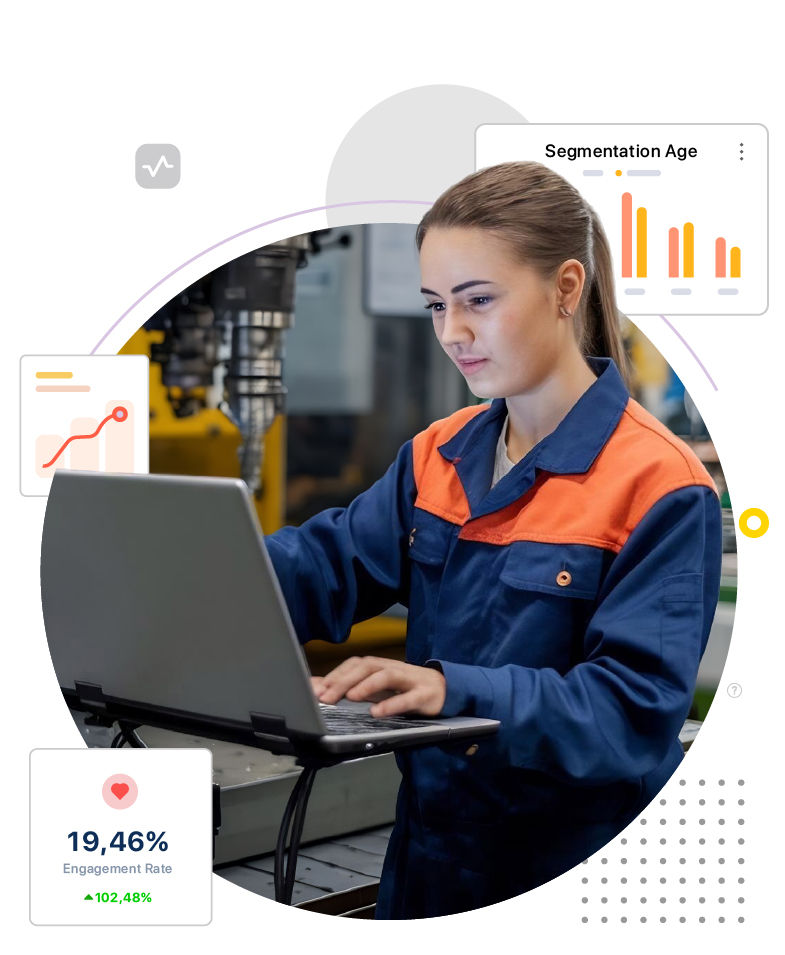

Where Machines Think, Materials Flow, and Decisions Accelerate

Communicates the shift from legacy-driven production environments to modern, tech-powered plants where data drives every decision in real-time

Unifying Factory Floors with Smart Systems That Talk

Detect Before Defect. Repair Before Failure

Right Specs. Right Time. Zero Waste

Usage : AI-based systems auto-generate optimal production schedules by evaluating capacity, workforce, machine status, and demand.

Impact : Improves throughput, reduces setup time, and ensures better on-time delivery rates.

Usage : MES synchronizes execution data with upstream (ERP, MRP) and downstream (QMS, PLM) systems for unified operations.

Impact : Reduces manual duplication, ensures data consistency, and supports end-to-end digital thread.

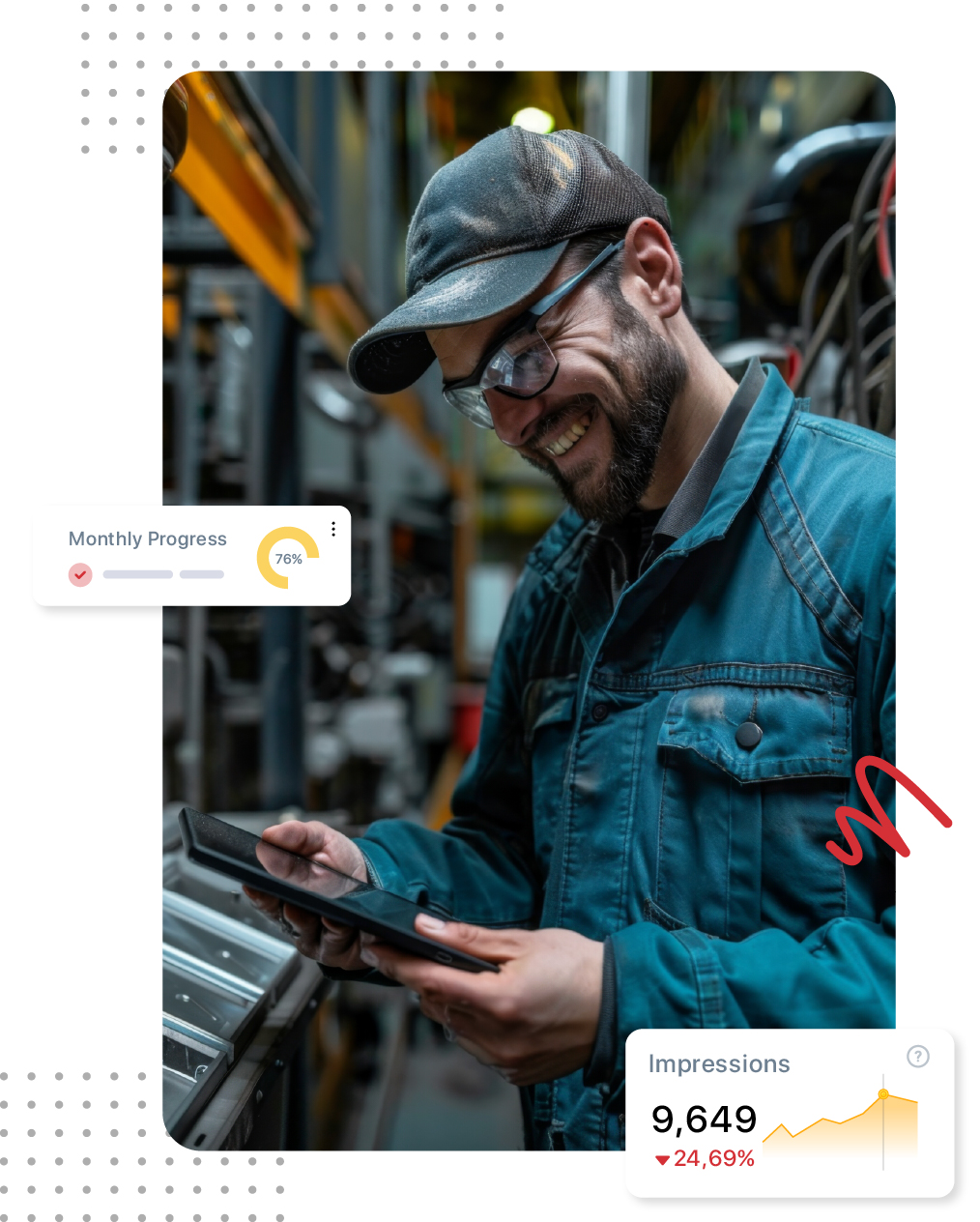

Factory Intelligence at Your Fingertips

Empowering Operators, Engineers, and Leaders — All in One Platform

Cut Energy, Reduce Waste, Boost Sustainability

Built for Industry 4.0. Ready for Industry 5.0

Usage : RFID, QR, and smart bins track raw material, components, and WIP movement across shop floors and warehouses.

Impact : Reduces material loss, prevents stock-outs, and supports just-in-time (JIT) manufacturing strategies.

Usage : Visual dashboards provide live OEE, output, quality trends, and maintenance stats to managers and leaders.

Impact : Enhances visibility, supports daily management, and enables data-driven operational excellence.

Usage : AI-powered vision systems inspect parts for dimensional accuracy, surface defects, and assembly precision in real time.

Impact : Increases defect detection accuracy, eliminates rework, and improves first-pass yield.

Usage : MES logs raw material consumption via barcode/RFID scans, IoT sensors, or automatic dispensing systems.

Impact : Enhances batch-level traceability, reduces material loss, and supports regulatory compliance.

Usage : IoT-connected machines and operator terminals feed live data on job progress, output quantity, scrap, and downtime to the MES.

Impact : Improves floor visibility, reduces reaction time to delays, and helps maintain throughput targets.

From Digital Job Cards to Real-Time Order Tracking

Find Defects Fast. Prevent Errors Forever