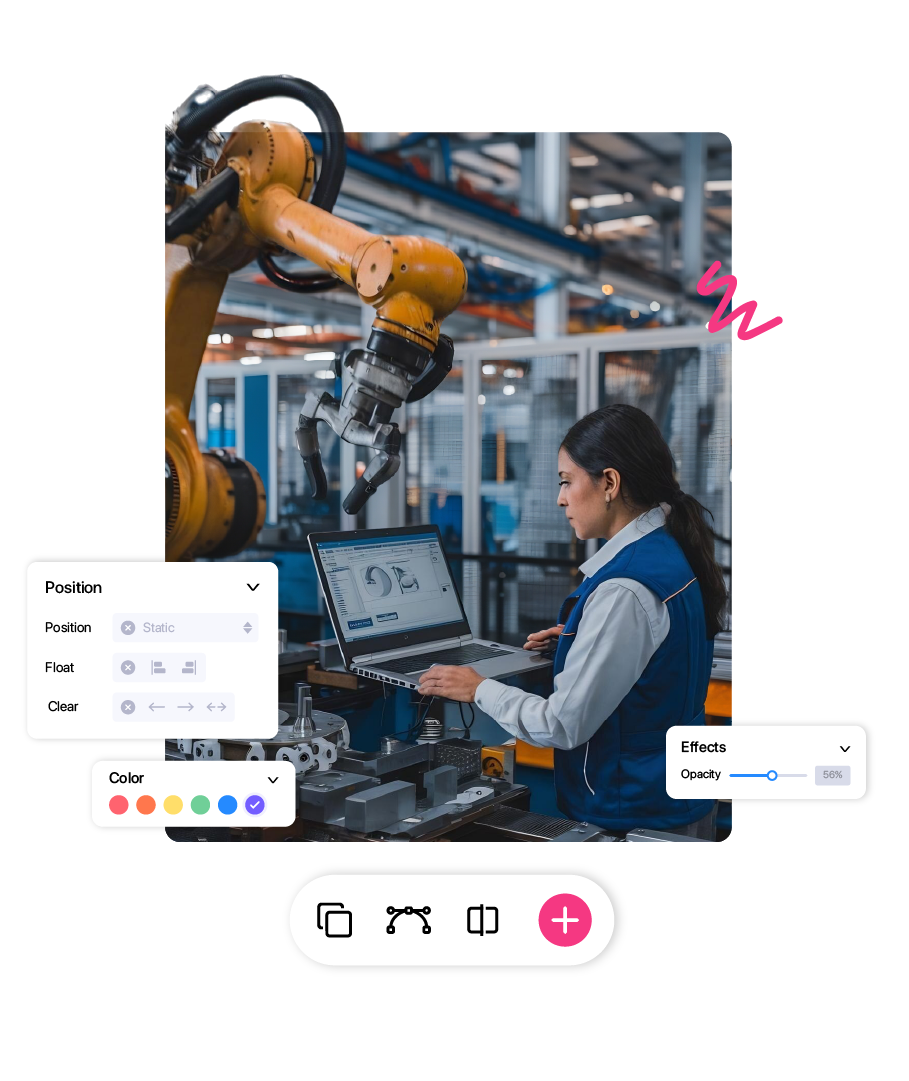

Empowering every team, from design studios to shop floors, to innovate together. Enable designers, product developers, sourcing agents, and manufacturers to ideate, modify, and execute in perfect sync.

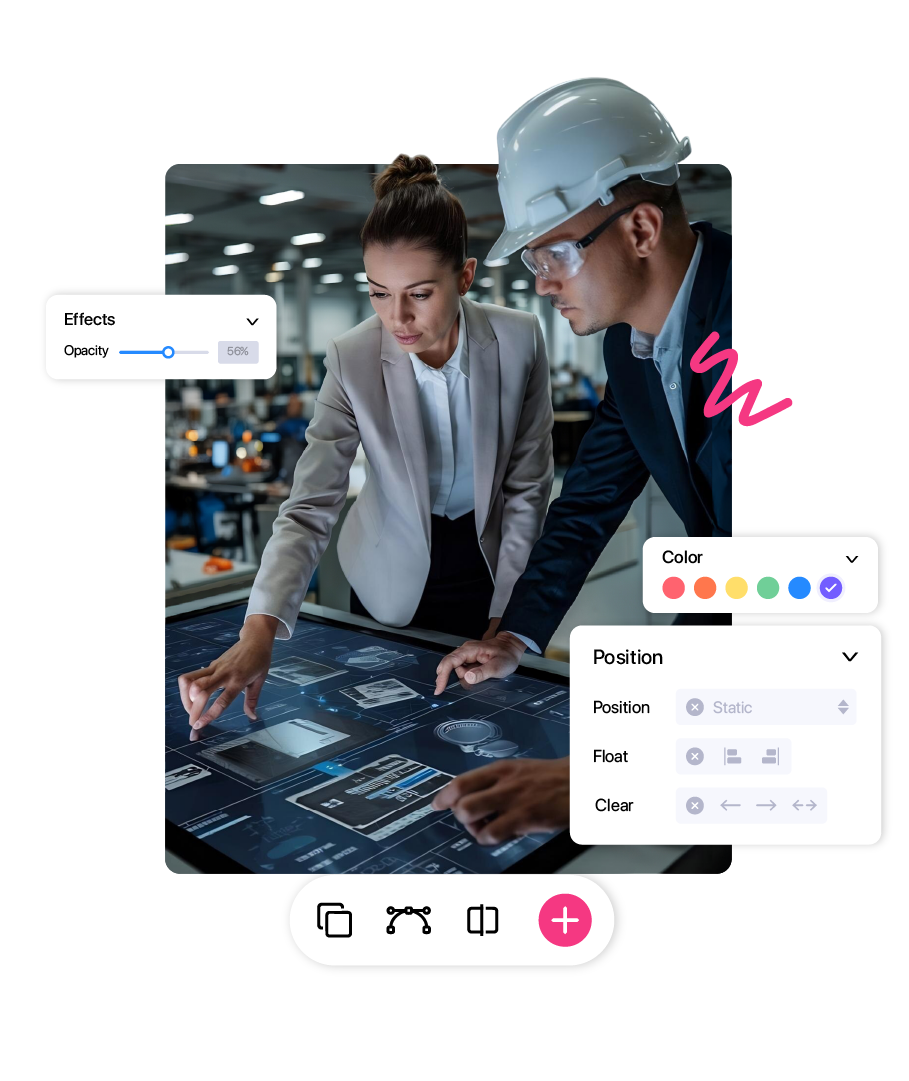

Work with every vendor as if they were in the room. Digital sample reviews, real-time feedback, quality approvals, and material collaboration—managed in one place.

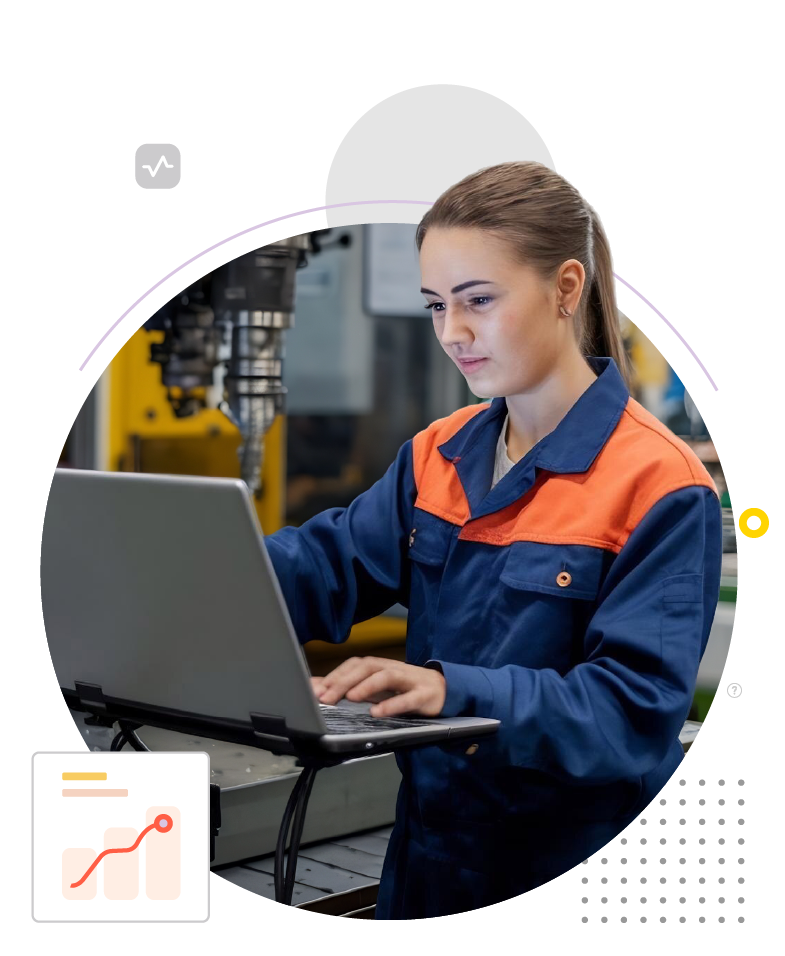

Let insights lead innovation and execution. AI-driven recommendations and predictive analytics that guide design feasibility, production scheduling, and risk mitigation

Learn from the line. Improve the next design. Real-time MES data feeds back into PLM to refine future collections based on production efficiency, quality outcomes, and operator feedback

Usage : Manage the entire lifecycle from design ideation to final production across collections, styles, BOMs, and tech packs.

Impact : Streamlines collaboration between designers, product developers, and sourcing teams. Reduces sample lead times, boosts product accuracy.

Usage : Track production status across units, lines, and workstations with live dashboards and alerts.

Impact : Enables real-time decision-making, reduces downtime, and boosts factory responsiveness.

One platform. Full traceability. Total control. Track materials, samples, production status, and quality audits across global suppliers with collaborative alerts and transparency.

Everyone aligned. Always on time. Integrated TNA calendars synchronize milestones across teams with automatic delay alerts, approvals, and workflow triggers.

Measure what matters — across people, products, and partners. Track efficiency, quality, cost, and delivery metrics from design teams to factory operators in a unified dashboard.

Design responsibly. Manufacture consciously. Embed ESG compliance, traceability, and sustainable sourcing across both product lifecycle and manufacturing execution workflows

Usage : Assign operations with clear routing instructions from CAD/CAM to finishing.

Impact : Eliminates ambiguity, reduces errors, and speeds up production workflows.

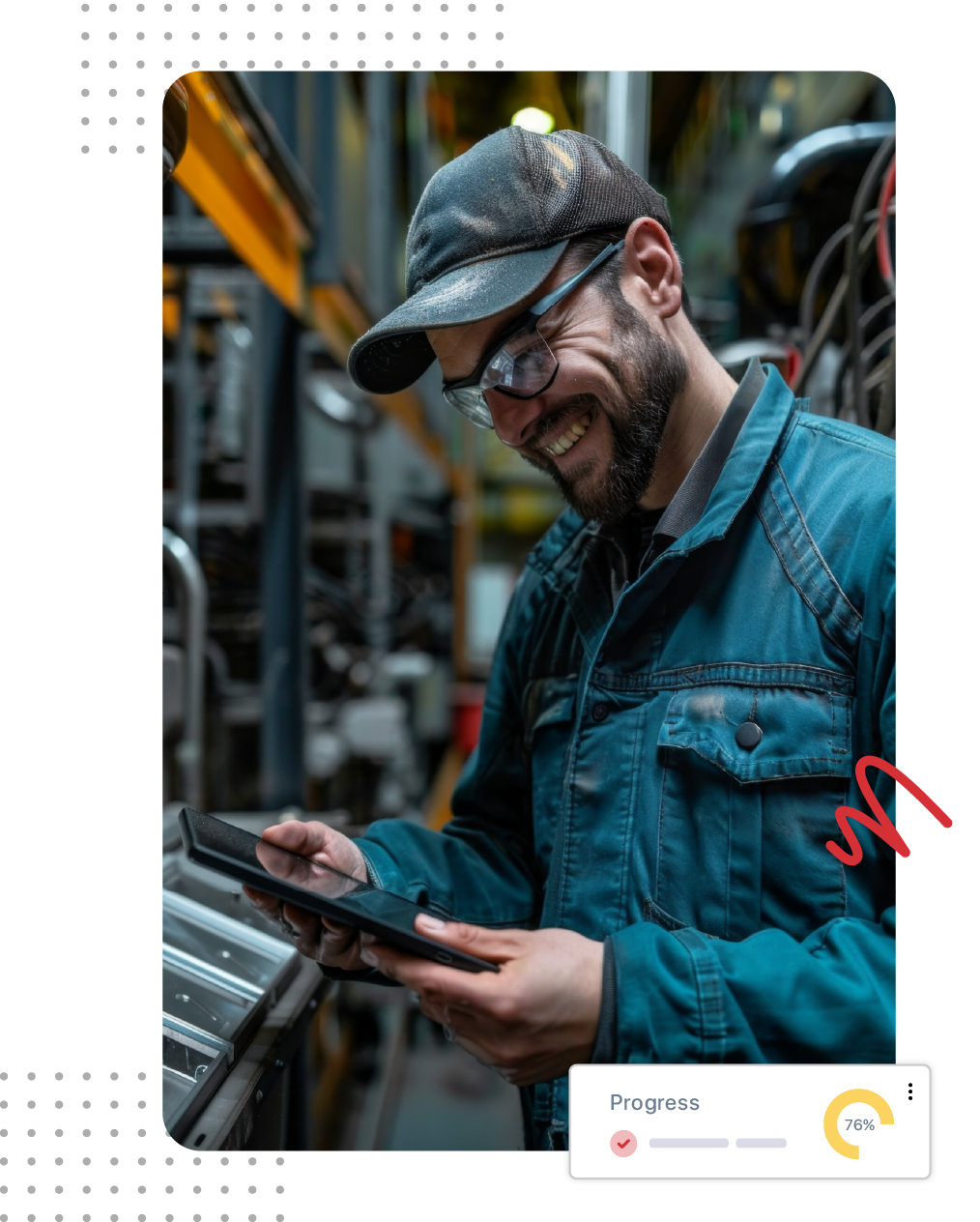

Usage : Enable floor supervisors to log issues, track outputs, and monitor operations using mobile devices.

Impact : Boosts on-floor agility and minimizes downtime.

Usage : Build and update BOMs, size specs, construction details, and attachments in one structured digital workspace.

Impact : Minimizes production errors, ensures version control, accelerates vendor communication.

Usage : Track real-time production progress across all units, workstations, and vendors.

Impact : Ensures delivery timelines, minimizes bottlenecks, maximizes production throughput.

Usage : Digitally map each workstation, operator, and machine for seamless task assignment, tracking, and feedback.

Impact : Increases transparency, eliminates manual tracking errors, and improves worker productivity.

Usage : Balance operator workload using AI-suggested optimizations and real-time input/output monitoring.

Impact : Reduces bottlenecks, boosts output consistency, and maximizes resource utilization.

Usage : Create dynamic cost sheets based on BOMs, labor, logistics, and overheads with instant margin visibility.

Impact : Enables profitable pricing decisions and rapid response to cost fluctuations.

Usage : Digitally capture defects, inline inspections, AQL checks, and corrective actions.

Impact : Lowers rejection rates, standardizes inspection reporting, and improves product quality.

Usage : Enable manufacturers, sourcing agents, and vendors to access styles, submit updates, and upload compliance documents.

Impact : Builds trust, transparency, and real-time visibility across your supplier network.

Usage : Maintain audit-ready logs for every transaction, operator action, and product movement.

Impact : Ensures traceability for buyers, auditors, and ESG compliance.

Usage : Monitor style performance, vendor BIs, production statuses, and sample cycle timelines.

Impact : Drives data-backed decisions, increases team accountability.

Usage : Suggest optimal vendors based on past performance, sampling speed, quality scores, and geography.

Impact : Reduces trial-and-error and optimizes sourcing.

Usage : Record operator performance, efficiency ratings, and assign jobs based on skill levels.

Impact : Enhances workforce management, speeds up line setup, and improves output per head.

Usage : Capture environmental metrics, vendor certifications, and material sustainability scores.

Impact : Empowers ethical sourcing and supports compliance with ESG and buyer regulations.

Usage : Sync product, order, and costing data across your ERP, PLM, and design systems.

Impact : Eliminates redundancy, streamlines operations.

Stay connected — on the go, on the floor, across the globe. Empower users from factories to fashion houses with mobile-first tools for real-time status updates, inspections, and decisions

Built to integrate. Ready to scale. Flexible APIs and seamless integrations that let your PLM-MES stack speak to design tools, enterprise systems, and machine data platforms